Magnetism and magnetic field measurement

Magnetic field strength, remanence, magnetic flux - what exactly are they?

Various measured variables can be determined in connection with magnets. Since there is often confusion about this topic, here is a brief overview. The exact definitions and physical principles can be found in the relevant literature.

Magnetic field strength (H)

The unit of measurement for magnetic field strength is amperes per meter (A/m), though amperes per centimeter (A/cm) and kiloamperes per meter (kA/m) are more commonly used due to the way the values are specified. Formerly, the unit of measurement was the Oersted (Oe). Since magnetic flux density (B), measured in Gauss (Gs) or Tesla (T), can be converted using a constant factor, magnetic field strength and flux density can be used interchangeably in practice, as can the units A/cm, kA/m, Oe, Gs, and T.

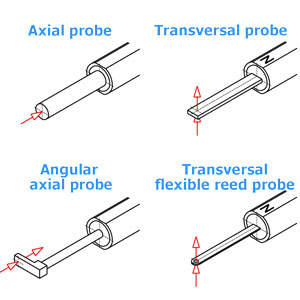

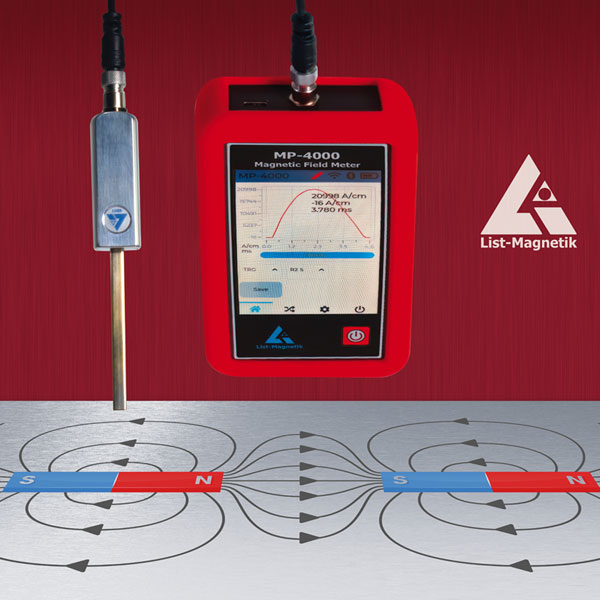

Devices that measure magnetic field strength are known as magnetometers, magnetic field meters, gaussmeters, or teslameters. Digital gaussmeters are particularly precise and user-friendly. Specialized magnetic field measuring systems and sensors are often used in industrial applications. Magnetic field measurement is essential for quality assurance and process control, particularly in industrial settings.

Remanence / Residual Magnetism

Remanence, also known as residual magnetism, is a special consideration of magnetic field strength. It is defined as the remaining field strength after the effect of a magnet or after a demagnetization process.

Remanence can also be measured using magnetic field meters, gaussmeters, or teslameters. These methods allow for precise analysis of magnetic field intensity, even with weak residual fields.

Magnetic flux

Magnetic flux (Φ, Phi) describes the total strength of a magnet. It is measured in volt-seconds (Vs), also known as Weber (Wb), or, formerly, Maxwell (Mx).

A fluxmeter is required to measure magnetic flux. These devices are more complex than handheld devices used to measure magnetic fields or permeability. They are often laboratory instruments, though there are also handheld devices with a connected Helmholtz torque coil. To measure magnetic flux density, you can use precise magnetic field measurement solutions.

What causes unwanted magnetism on steel parts?

Magnetic measurements are essential not only in research and development but also in quality assurance. For example, magnetic steel parts can cause problems due to tool wear from adhering iron filings. Sensors can also be affected. The causes of magnetism cannot be defined broadly. Steel parts can easily become magnetized by the Earth's magnetic field, which aligns the material's elementary building blocks in the direction of the field. Steel bars, for instance, become magnetized due to vibrations during transport.

Magnetic field sensors and magnetic load handling attachments, which are universal and gentle on materials, can cause residual magnetism if used.

First, determine the residual magnetic field strength using a suitable test method. If the residual magnetization exceeds the tolerances, demagnetization is recommended before installing the finished part to minimize the influence of transport on the remanence.

Electromagnetic high frequency fields

Magnetic field measuring devices from List-Magnetik are suitable for analyzing direct and alternating magnetic fields up to 20 kHz. They have a measuring range from 0.01 mT (10 µT) to 5 T, which is at least the strength of the Earth's magnetic field. However, these devices are not suitable for measuring electromagnetic high-frequency fields for EMC testing or electrical fields in the range of a few µT. List-Magnetik does not sell special EMC measuring devices for this purpose.