Coating Thickness Meter MEGA-CHECK DX

The MEGA-CHECK DX Coating Thickness Gauge offers the ability to connect a wide variety of probes to measure coating thickness on metal.

Advantages of the MEGA-CHECK DX Coating Thickness Gauge

The List-Magnetik MEGA-CHECK DX Coating Thickness Gauge can be connected to a wide range of specialized digital probes. Applications on very small apertures, thick layers and small measuring points are easily possible. Special functions such as scan measurement on rough surfaces and duplex measurement on galvanized and additionally coated steel complete the range of features.

Trouble-free and precise measurement in layer thickness measurement

A completely newly developed digital probe technology ensures very stable measurements thanks to a high sampling rate. The signals are digitized in the probe for absolutely interference-free and precise measurements. The result is highly accurate, reproducible coating thickness measurements.

Wide range of probes for the coating thickness gauge

List-Magnetik offers a wide range of probes for ferrous metals (iron and steel) and non-ferrous metals (non-ferrous metals such as aluminum, brass, copper, bronze, and non-magnetic stainless steel) as well as combined probes with automatic base material detection.

Coating thickness measurement with the MEGA-CHECK DX and a DX6-FT probe on a steel bridge - the famous "Blue Wonder" in Dresden. Many thanks to Mr. Dieter Recknagel from HAMAX® Unternehmungsbetreuung, Dresden, for the photo.

Thickness measurements on a wide variety of coatings

The magnetic induction method allows the measurement of varnish, paint, plastic, rubber, ceramic, galvanized and electroplated coatings on steel. The eddy current method allows you to measure insulating coatings (paint, varnish, plastic, anodizing) on non-ferrous metals.

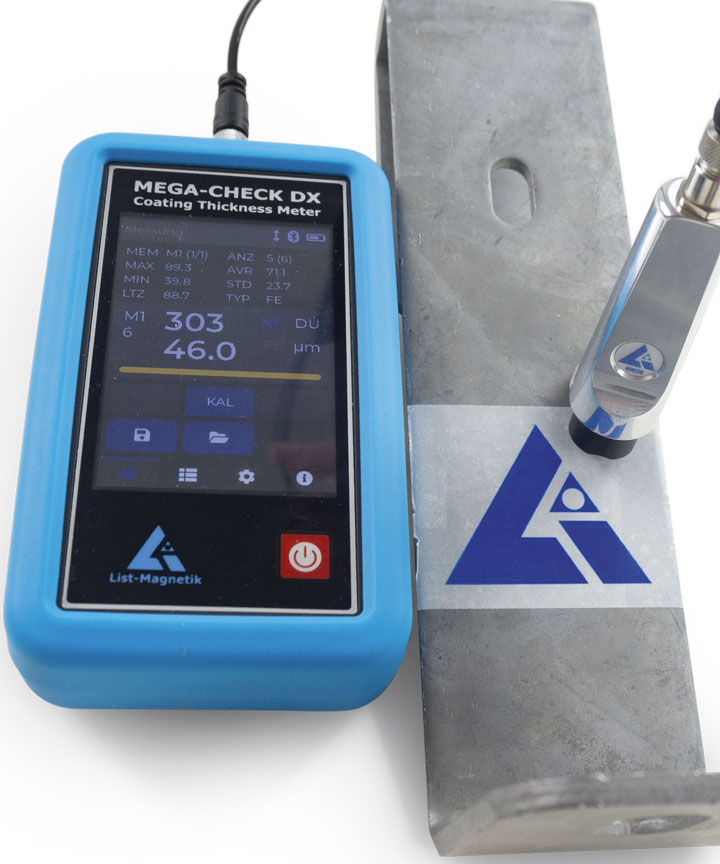

Graphic display

The coating thickness gauge is equipped with a graphic LCD touch panel with innovative user guidance and a resolution of 320x480 pixels. The blue silicone frame effectively protects the housing from damage.

Data Logger and Interfaces

With the flexibly divisible measured value memory, the freely definable calibration memories, and the wireless interface for Windows, Android, or iOS, you have every option for recording and further processing your measured values.

Remote measurement control

The instrument is equipped with an SCPI interface, which allows remote measurement and data transmission in line operation. The connection is via USB, which also ensures power supply and continuous operation.

Special functions: Scan, Duplex

The scan function allows a workpiece to be scanned over a rough surface and the data to be statistically evaluated. The additional analog display completes the visualization of the measured values. This allows you to see trends and peaks even out of the corner of your eye.

The duplex function simultaneously records the individual layer thicknesses when measuring insulation layers on galvanized steel parts.

Scan Measurement |

Duplex Measurement |

|---|---|

| Want to continuously scan a coating and determine the minimum and maximum values? Scan measurement provides a graphical coating thickness curve with statistical analysis. | Want to evaluate galvanized and coated steel in one step and see both the zinc layer and the paint layer together? With the duplex measurement option, both can be quickly displayed simultaneously and statistically analyzed separately. |

|

|

Continuous operation

Power can be supplied by three AA batteries or an external power source connected via USB. This allows you to run the gauge from a power supply or AC adapter.

Replaceable Gauge Probe Cable

The two-sided pluggable probe cable connects the display unit to the digital probe and can be easily replaced if the cable breaks.

High quality

All List-Magnetik MEGA-CHECK coating thickness gauges are high quality products "Made in Germany".

Quality assurance through the coating thickness gauge

A coating thickness gauge is typically used in the quality assurance of coating processes. For example, to determine the thickness of a coating. It is also suitable for testing vehicles or steel structures and in the field of fire protection (determining the coating thickness of steel doors). In addition to being a paint thickness gauge, it can also be used to measure rubber coatings, anodized aluminum, and galvanized coatings.

MEGA-CHECK DX vs. Basic / Profi / Master

The MEGA-CHECK DX has replaced the MEGA-CHECK Basic / Profi / Master models, which have been well proven for 15 years. The measurement technology of the new generation of DX probes has been significantly improved. A major advantage is the graphic display with many additional functions such as scan measurement and analog display. MEGA-CHECK DX also offers a more convenient memory function. The wireless interface to Windows PCs as well as Android and iOS mobile devices can be used to exchange data.

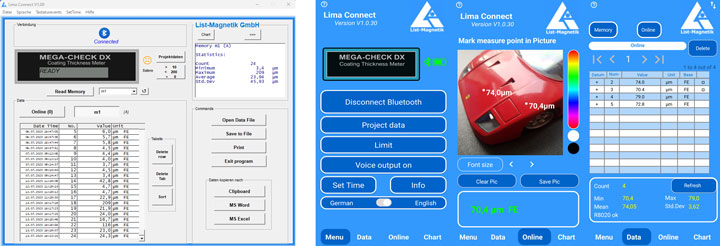

Manage and Share Measurement Data with Free App

To further process your measurement data, you can pair your coating thickness gauge with Android and iOS mobile devices or communicate with a Windows PC. Wireless technology makes this possible. With the Lima Connect app, you can manage projects and assign measurement points to a photo. Measurement results can be statistically evaluated and graphically displayed. The app is available for free for Android, iOS and Windows.

|

Technical data of the probes: |

|||||

|---|---|---|---|---|---|

| Model | FE or NF | Description |

Measuring range

|

Smallest Area

|

Smallest

curvature radius

|

| DX52-D | FE + NF combined | Dual probe with sliding sleeve and prism |

FE 0-5000 µm

NF 0-2000 µm |

ø 8 mm

|

convex: FE 4 mm,

NF 6 mm concave: 38 mm

|

| DX52-DP | FE + NF combined | Dual probe with sliding sleeve and prism, pivotable |

FE 0-5000 µm

NF 0-2000 µm |

ø 8 mm

|

convex: FE 4 mm,

NF 6 mm concave: 38 mm |

| DX5-F | FE | Standard FE probe with sliding sleeve and prism |

0-5000 µm

|

ø 4 mm

|

convex: 4 mm

concave: 38 mm |

| DX5-FP | FE | Standard FE probe with sliding sleeve and prism, pivotable |

0-5000 µm

|

ø 4 mm

|

convex: 4 mm

concave: 38 mm |

| DX1-F | FE | Spring-loaded probe for small parts and complex surfaces |

0-1000 µm

|

ø 2 mm

|

convex: 1 mm

concave: 6 mm |

| DX1-FT | FE | Transverse rod probe for small interiors and tubes |

0-1000 µm

|

ø 2 mm

|

convex: 2 mm

concave: 16 mm |

| DX6-FT | FE | Transverse rod probe for small interiors and tubes |

0-6000 µm

|

ø 3 mm

|

convex: 2 mm

concave: 8 mm |

| DX7-F | FE | FE probe for thick layers with spring-loaded guide and prism |

0-7000 µm

|

ø 4 mm

|

convex: 4 mm

concave: 38 mm |

Models and scope of delivery Coating Thickness Meter MEGA-CHECK